Portfolio

Hygiene and Personal Care

Products for the cleaning and hygiene markets including soap dispensers, vacuum cleaners, single disk rotary machines and air fresheners

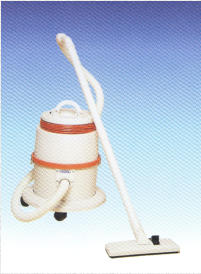

Jeyes Hygiene Ensign Scout Tub Vacuum Cleaner (1989)

To design a small tub vacuum cleaner. The machine should be:

•

Light & easy to carry with a recessed carrying handle

•

Use standard/common parts where possible

•

Have a built in thermal overload

•

Be able to be used with or without paper or cloth dust bags

•

Manufactured & assembled in house.

•

Utilise CINPRES technology to reduce manufacturing costs

Project Budget: £50,000.00

Responsible for:

•

The design & development of the product.

•

The manufacture & testing of engineering prototypes & models

•

The determination of product specifications & operating parameters.

•

Initial product costings.

Notes:

By

using

some

parts

from

the

SCOUT

project

&

where

possible

parts

from

the

SDV

mk.1

the

machine

was

produced

in

house

&

on

the

same

production

line.

The

use

of

common

parts

not

only

resulted

in

less

SKU’s

&

fewer

service

spares

parts,

but

also

in

more

flexibility

allowing

production

to

switch

between

models

&

versions

almost

instantly.

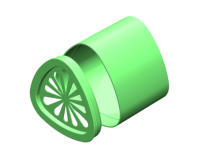

UNILEVER LEVERFRESH Gel Air Freshener (1991)

To

redesign

the

current

gel

air

freshener

container

in

order

to

maintain

supply

as

the

existing

cheap

looking

hand

cream

pot

is

to

be

deleted

from

the

suppliers

product

range.

This

gives

the

opportunity

to

reduce

the

selling

price

by

£0.05

per

unit & increase sales through:

•

Improved shelf appeal

•

Easier “stackability” on shelf to maximise shelf space

•

Greater attractiveness to end users

•

Improved Security

•

Improved fragrance.

Project Budget: £26,000.00

Role: Technical Expert responsible for:-

·

The

evaluation

of

the

prototype

parts

&

translation

of

the

conceptual

designs into production.

·

The

definition

of

material

specifications

to

meet

the

requirements

of

the

project brief.

·

Ensuring

all

3rd

party

sourced

tooling,

materials,

suppliers

&

components

meet the companies requirements

The new gel pots are now selling successfully, the unique hidden “locking

bayonet” feature is proving very successful in reducing thefts from public

buildings & hotels. Ensuring all 3rd party sourced tooling, materials, suppliers &

components meet the companies requirements.

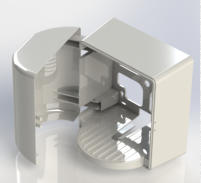

UNILEVER LEVERLINE Range (1992)

A

range

of

products

that

have

been

developed

by

Lever

Industrial

(Maarssen)

in

conjunction

with

a

leading

Dutch

design

consultant.

The

system

will

be

marketed

under the Leverline brand name & will include the following products:

·

Liquid Soap Dispenser

·

Hand Drier (Hot Air, 230V)

·

Air freshener (battery operated)

Role :

UK

Project

Leader

(Design)

Responsible

for

the

local

management

of

the

design

&

development

phases

of

the

international

project

to

ensure

that

marketing

briefs,

specifications, time-scales & capital expenditure budgets are met.

•

To

evaluate

the

prototype

parts

&

translate

the

conceptual

designs

into

full

working drawings.

•

To

define

material

specifications

to

meet

the

requirements

of

the

project

brief.

•

To source all tooling, materials & components.

•

To

set

up

an

in

house

production

facility

to

manufacture

&

distribute

the

products.

Notes:

The

initial

product

styling

for

the

Leverline

range

was

conceived

by

colleagues

in

Holland

with

the

aid

of

design

consultants

Ninaber

Peters

&

Krouwl

of

Leiden.

The

subsequent

tasks

of

integrating

bespoke

electronics

&

designing

the

components

for

manufacture,

production,

assembly

&

fitness

for

purpose

were

handed

over

to

the High Wycombe design team.

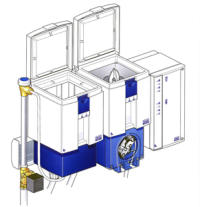

Unilever Compac MWW Dosing System (1993—1995)

To

progress

from

the

"concept"

stage

through

the

"detail"

stage

to

production

a

dispensing

system

that

has

been

developed

by

Lever

Industrial

(Maarssen)

in

conjunction

with

a

leading

Dutch

design

consultant.

The

function

of

the

dispenser

is

to

automatically

dose

detergent

&

rinse

aid

into

industrial

mechanical

dish

washing

machines. The role of the UK design team is to:

•

Evaluate

the

prototype

parts

&

translate

the

conceptual

designs

into

full

working

drawings.

•

Define material specifications to meet the requirements of the project brief

•

Source all tooling, materials & components.

•

To set up an in-house production facility to manufacture & distribute the products.

Project Budget: £100,000.00

Notes:

The

initial

product

styling

for

the

Leverline

range

was

conceived

by

colleagues

in

Holland

with

the

aid

of

design

consultants

Ninaber

Peters

&

Krouwl

of

Leiden.

The

subsequent

tasks

of

integrating

bespoke

electronics

&

designing

the

components

for

manufacture,

production,

assembly

&

fitness

for

purpose

were

handed

over

to

the

High

Wycombe

design team.

UNILEVER TASKI Single Disk Floor Cleaning Machines (1996—1998)

To

design

&

develop

a

range

of

single

disc

floor

cleaning

machines

which

are

an

evolution

of

the

current

products.

The

new

products

must

establish

a

strong

corporate

identity

or

"family

image"

which

will

support

their

progressive

introduction

over

the

next six years, the key elements of the design philosophy being:

•

eye catching futuristic image

•

corporate identifiable range with "family look"

•

low profile simple 'soft line' styling

•

integrated modular construction of machine & accessories

•

commonality of major components

•

use of lightweight plastic components

•

incorporation

of

new

component

&

manufacturing

technologies

where

appropriate

•

enhancement of cost competitiveness, incorporation of new USPs

•

maintenance of traditional perception of good reliability

•

designed for 3 year warranty

At

the

end

of

1996

the

High

Wycombe

Innovation

Centre

for

machines

was

closed

resulting

in

all

design

&

development

work

being

transferred

to

Switzerland.

The

concept

stage

of

this

project

had

been

completed

&

prototypes

of

some

of

the

variants

produced using rapid prototyping techniques.

Atrium Solo 2 Air freshener (2011-2012)

Commissioned

to

design

from

scratch

a

battery

powered

air

freshener

incorporating

the

patented

Atrium

electrostatic

dispensing technology.

Dolphin Dispensers Jumbo Roll Paper Dispenser

(2013)

Commissioned

to

Design

and

3D

model

a

Paper

Dispenser

for Hand towels

AWT Limited 2019