Portfolio

Industrial and OEM

Industrial and OEM products and equipment

TCL: Cryogenic Parts and Assemblies (2007)

Commissioned

to

produce

standardised

3D

parametric

models

for

a

number

of

company

specific

assemblies,

then

use

said

assemblies

to

produce

a

cryogenic

piping

installation from given data.

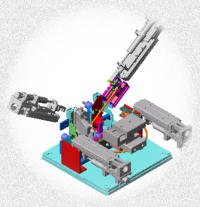

P2I: Sliding Frame For Fabric winder In A Vacuum deposition

Chamber (2011)

Commissioned

to

carry

out

the

conceptual

design

of

a

special

purpose

machine

to

allow

processing

of

continuous

rolls

of

fabric

in

P2i's

existing

2m

x

1m

x

1m

VACUUM

chamber..

PARAGON PLASTICS: Push-Fit Pipe Jointing System For 15mm

Domestic Hot & Cold Water (1982)

Project Brief:

To

develop

an

economical,

simple

push

fit

joint

for

use

with

Copper,

Polybutylene

&

PVCc

pipes.

The

styling

should

be

neat

&

slim

line.

The

joint

should

be

able

to

be

removable/reusable

without

special

tools.

The

joint

should

be

capable

of

being

included

in

the

following

fitting

configurations:

Coupler,

Double

Socket.

Elbow,

45

0

Double

Socket.

Elbow,

90

0

Double

Socket.

Elbow,

90

0

Double

Socket.

Equal

Tee,

Triple Socket. End Cap.

Notes:

The

project

was

completed,

the

result

was

a

fully

developed

joint

that

was

ready

for

productionising into the range of fittings as detailed above.

Market

research

at

the

time

showed

that

professional

plumbers

preferred

using

Copper

pipes

&

soldered

joints

&

that

DIY

users

did

not

have

the

confidence

to

trust

plastic

components.

These

sensitivities

resulted

in

the

project

being

shelved

until

the

use

of

plastics

in

place

of

traditional

materials

was

accepted.

The

product

is

now

on the market.

PARAGON PLASTICS: 90mm—180mm Push-Fit Pipe Jointing System

For Potable Water (1981)

Project Brief:

To

develop

an

economical,

simple

push

fit

joint

for

use

with

Copper,

Polybutylene

&

PVCc pipes. The styling should be neat & slim line.

The

joint

should

be

able

to

be

removable/reusable

without

special

tools.

The

joint

should

be

capable

of

being

included

in

the

following

fitting

configurations:

Coupler,

Double

Socket.

Elbow,

45

0

Double

Socket.

Elbow,

90

0

Double

Socket.

Elbow,

90

0

Double Socket. Equal Tee, Triple Socket. End Cap.

Notes:

When

paragon

Plastics

was

bought

by

Polypipe

the

“Push-Fast”

range

of

products

was

licensed

to

a

“competitor”,

subsequently

Polypipe-Paragon

have

remarketed

the

range under their own flag.

PARAGON PLASTICS: 1/2” - 4” and 20mm - 110mm Socket Fusion Weld

Pressure Pipe Fittings (1980).

To design a range of socket fusion fittings to comply with the relevant British, DIN &

other international standards.

The design should be adaptable for the production of parts in PP (both metric &

imperial sizes), PVCu, ABS & PE.

The range of products will include:

•

Straight Coupler

•

45

0

Elbow

•

90

0

Elbow

•

90

0

Swept Bend

•

90

0

Tee

•

Stub Flange

•

Full Face Flange

•

Long Reducer

•

End Cap

Project Budget: £50,000.00

Responsible for:

•

The design & development of the products.

•

The manufacture & testing of engineering prototypes & models

•

The determination of product specifications & operating parameters.

•

Initial product costings.

Detail Design Of 3 Shoe Hangers (2005)

Take

the

Concept

Model

of

each

of

3

Shoe

Hanger

Variants

and

produce

parts

suitable

for

Open/Shut

Tooling.

Parts

to

include:

draft

analysis,

parting

face

analysis,

split

line

detail,

gate

position,

ejector

pin

positions

and

advice

on

mouldability.

Detail Design of a Modular Currency Recognition System (2005)

Commissioned

to

make

ready

for

production

and

create

fully

detailed

2D

drawings

for

all parts including primary and secondary packaging.

Concept

&

Detail

Design

of

a

Modular

Currency

Recognition

System

(2005—2006)

Commissioned

to

produce

concept

designs

for

approval,

then

detail

selected

design

for

SLA parts to be produced prior to productionisation by the client.

Thermostatic Shower Valve (2000)

Commissioned

to

take

the

conceptual

prototype

and

create

production

ready

parts

and

assembly

drawings

a

fully

detailed

BOM

and

operating

instructions

in

readiness

for volume manufacture.

Parts For Coffee Machine (2002)

Commissioned

to

take

the

conceptual

prototype

and

create

production

ready

parts

and assembly drawings in readiness for volume manufacture.

Detail Design of a “Turtle” Step Stool (2002)

Commissioned

to

take

the

conceptual

model

and

create

production

ready

part

and

fully detailed drawing in readiness for tooling manufacture.

Design of outdoor floodlighting products (2002)

Commissioned

to

take

the

conceptual

prototype

and

create

production

ready

part

and

assembly

drawings

and

a

fully

detailed

BOM

in

readiness

for

volume

manufacture.

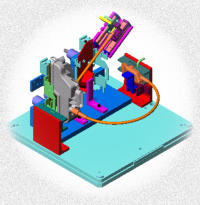

RENAULT Door Lock Assembly and Test SPM

(1999)

Commissioned

to

design

a

special

purpose

machinery

for

the

assembly

and

testing

of

automotive

door

locks

for

the

“next generation” of Renault cars.

One Man Windshield Installation Tool(2010/11)

Commissioned

to

take

the

conceptual

model

and

create

production

ready

part

and

fully detailed drawing in readiness for tooling manufacture.

Boot For Airbus Riveting Tool(2012)

Problem:

When

assembling

the

Carbon

Fibre

wing

panels

the

nut

driver

can

jump

out

of

it’s

location

and

damage

the

carbon

fibre

panel

which

would

then

have

to

be

replaced.

Solution:

A

rubber

Boot

to

hold

the

nut

driver

captive—hence

eliminating

the

problem.

Clog Sole Design(2013)

My

client

is

a

manufacturer

of

hand

made

clogs,

he

has

made

a

device

to

automatically

machine

the

clog

soles.

I

was

commissioned

to

produce

a

3D

Generic

clog

sole

model

and

then

generate

a

SolidWorks

DESIGN

TABLE

for

the

range

of

adult

sizes.

Free Standing Frame Design(2013)

My

client

is

an

Artist

who

commissioned

me

to

design

a

free

standing

frame

system

to

display

a

range

of

screens.

The

screens

come

in

a

range

of

sizes

and

can

lock

together in any combination of sizes.

The

image

shows

a

frame

with

clear

glass

screens,

however,

the

client

was

in

the

process

of

creating

a

number

of

bespoke

screen

designs

for

clients

I

was

commissioned to produce 3D CAD models and 2D Detail Drawings for manufacture.

Sleeping policemen(2017)

Commissioned

to

refresh

and

re-design

my

client’s

current

5mph

and

10

mph

speed

bump products.

The

new

version

would

include

a

revolutionary

Rail

mounting

system

to

reduce

lateral

drag

from

vehicles

virtually

eliminating

the

bumps

being

ripped

from

the

road

surface..

Right Hand Image shows conceptual design, left Hand Image shows production model

200 Litre Grit Box(2012)

Commissioned

to

take

an

artists

2D

sketch

and

create

3D

parts,

assemblies

and

fully

detailed

drawings

in

readiness

for manufacture.

AWT Limited 2019

2D to 3D Conversion (2019)

Commissioned to convert around 2500 .dwg Seal variants into 3D solid models and to deliver:

•

A 2D .pdf file for each part

•

A 3D Solid model

Stackable Foundation system For Garden Buildings (2021)

Commissioned to design a Foundation System For Garden Buildings:

•

Must be stackable

•

must have common Lid/Base

•

And

to

supply

2D

drawings

and

part

specifications

so

production

Parts

can

be

manufactured.

Precision Ball Slide(2019)

Commissioned to design a precision ball slide foe a 4mm diameter probe

•

Sleeve matl: brass

•

Ball Matl.: stainless steel