Portfolio

Prototypes And Conceptual

Prototype parts and equipment

Tails Cocktails(2010)

Commissioned

to

take

the

conceptual

model

and

create

production

ready

part

and

fully detailed drawing in readiness for prototype tooling manufacture.

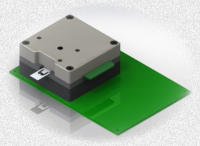

Prototype Blood Testing Device(2011)

Commissioned

to

take

the

current

electronics

design

and

create

a

prototype

device

to

test

“proof

of

principal”

To

create

3D

parts,

assemblies

and

fully

detailed

drawings

in

readiness for manufacture.

Prototype Bottle Cap (2012)

Commissioned

to

take

the

conceptual

model

and

create

production

ready

part

and

fully detailed drawing in readiness for tooling manufacture.

Prototype Delayed Action Mechanism (2012)

Commissioned

to

design

from

scratch

a

mechanism

that

could

be

retro

fitted

into

the

companies

self

injection

devices

to

indicate

that

the

syringe

had

fully

emptied.

And

to

deliver 3D models and fully detailed drawing in readiness for prototype manufacture.

Prototype 20ml Dose Cap(2012)

Commissioned

to

take

the

conceptual

model

and

create

production

ready

part

and

fully detailed drawing in readiness for prototype tooling manufacture.

Prototype Air Freshener(2012)

Commissioned

to

take

the

conceptual

model

and

create

production

ready

parts

and

fully detailed drawing in readiness for prototype tooling manufacture.

Prototype Injection Mould tool(2012)

Commissioned

to

take

the

conceptual

model

and

create

fully

detailed

core

and

Cavity data in readiness for prototype tooling manufacture.

Prototype Air Freshener(2012)

Commissioned

to

take

the

conceptual

model

and

create

production

ready

parts

and

fully detailed drawing in readiness for prototype tooling manufacture.

Headphones(2013)

The

client

designs

and

manufactures

bespoke

audio

technology

(such

as

noise

reduction)

for

OEM

headphone

manufacturers.

Currently

they

demonstrate

their

technology

by

fitting

it

to

“off

the

shelf”

headphones

manufactured

by

a

well

known

brand.

It

is

the

intention

of

the

client

to

produce

an

“own

brand”

product—initially

to

demonstrate

their

technology

to

prospective

customers,

however,

they

may,

in

the

future

decide

to

market

a

range

of

technologically

advanced

headphones

of

their

own.

It

was

my

remit

to

design

an

unbranded

product

that

could

be

easily

branded

to

suit

any prospective customer, or be branded with the clients logo.

Bottle development

Commissioned

to

develop

a

bottle

with

a

wave

form

feature

around

it’s circumference..

Airfreshener(2017)

The

client

has

designed

this

product

and

commissioned

tooling

to

produce

prototype

mouldings.

However,

the

product

does

not

function

as

expected.

It

was

our

remit

to

evaluate

the

design

and

make

adjustments

to

enable

the

product

to

perform as it should.

Urban Farm(2016)

The

Urban

Farming

Company

is

a

social

enterprise

with

a

passion

for

innovation,

the

environment

and

food

sovereignty.

they

apply

the

key

principles

of

sustainable

development

to

create

balanced

growing

systems

that protect natural ecosystems, support local communities, educates our children and nourishes families.

This project is their first foray into desktop growing.

We

were

commissioned

to

take

the

client’s

Sketches

and

generate

3D

CAD

Models

and

then

Manufacture

prototypes by 3D printing the parts In-House.

Option 1.

a

system

that

would

allow

optimal

growth

via

computer

aided

control

of

lighting,

heating

,

watering

and

nutrition.

from

a

bespoke

seed

pod

(Green

part)

and

deliver

video feedback via a smart phone, tablet etc..

Option 2.

a

“lite”

option

that

could

clip

onto

a

standard

plant

Pot

and

deliver

video

feedback

to

a smart phone, tablet etc.

Watering, lighting, heasting and nutrition would be administered manually.

AWT Limited 2019

Cool Box For Doorstep Milk Storage. (2021)

A

2

Part

Storage

Box

with

hinged

lid

and

some

thermal

insuation

for

keeping

milk

fresh for 8 - 12 hours while home owner may be out to work for day.

Toffee Tray. (2021)

A tray to produce “random” shaped toffee pieces.

Proposal to replace a slab of toffee being manually broken before packaging.

Dairy Product Doorstep Storage Crate. (2022)

A

2

Part

Storage

Crate

with

Internal

dividers

and

some

thermal

insuation

for

keeping

milk fresh for 8 - 12 hours while home owner may be out to work for day.

Unilever Detergent Scoop (2014)

Commissioned

to

design

two

scoops

with

24ml

and

34ml

capacity

for

dosing

detergent powder.

Also commissioned to design prototype injection mould tool to produce parts.

Lampshade (2015)

Commissioned

to

design

a

lampshade

that

has

an

integral

feature

to

allow

a

number

of

different

“slides”

to

be

inserted,

for

example

a

unicorn

pattern

for

a

girl’s

room,

a

Robot pattern for a boy’s room, etc.

Medical Valve (2018)

Commissioned to design prototype tooling to produce a medical Valve.